Product Information/ PRODUCTS /Multi-functional contact angle, surface free energy, and surface tension measurement instrument FLATSCAN

Multi-functional contact angle, surface free energy, and surface tension measurement instrument FLATSCANMulti-functional contact angle, surface free energy, and surface tension measurement instrument FLATSCAN

specification:

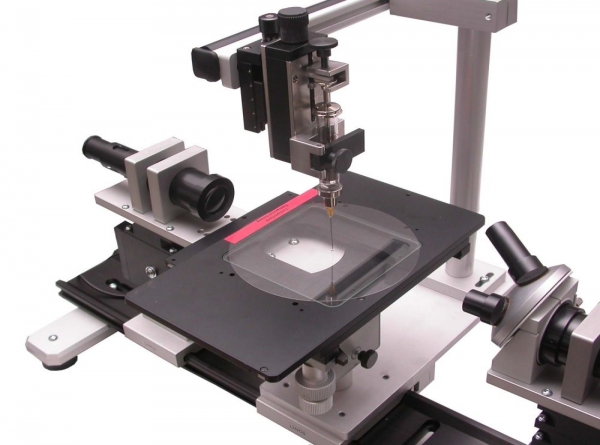

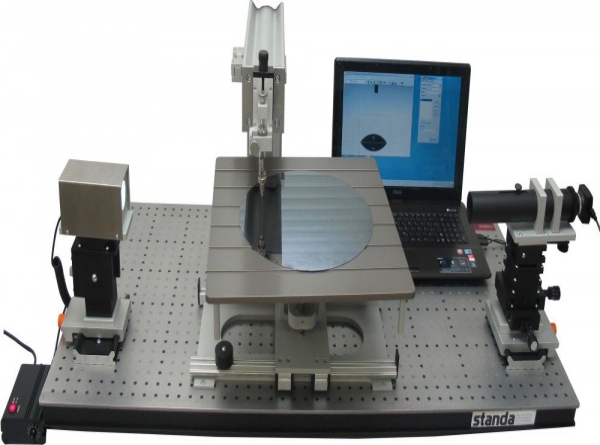

FLATSCAN is a non-contact automatic 2D or 3D measurement instrument that can measure the curvature, warpage, surface profile, and flatness of all reflective surfaces, such as wafers, glass, and metal surfaces. It can also calculate the film stress of these surfaces through software analysis.

DESCRIPTION

Product Features:

- High measurement accuracy

- Non-contact measurement

- Option to choose 2D or 3D measurement

- Can measure approximately any size of surface

- Suitable for highly curved surfaces such as X-ray mirrors (multilayer film mirrors) and silicon wafers

- Capable of detecting higher degrees of curvature

Measurement Principle:

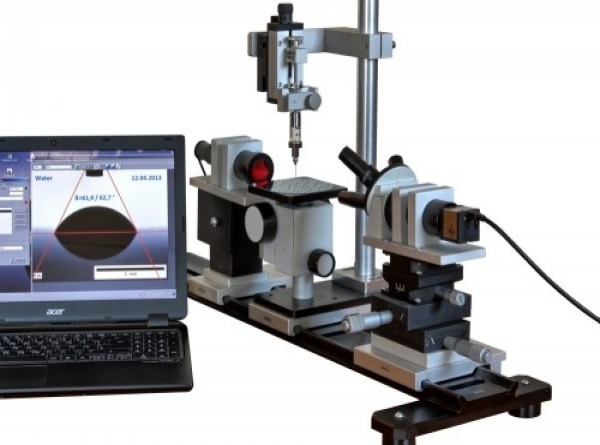

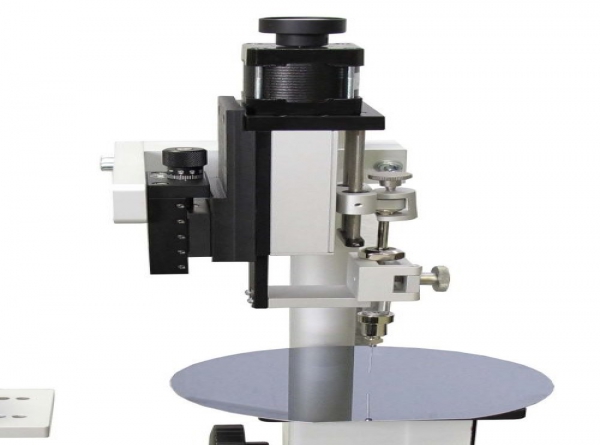

The incident light perpendicular to the sample surface forms a reflection angle after being reflected from the surface, which varies with different surface profiles. FLATSCAN utilizes the variations in the reflection angles between measurement points to calculate and reconstruct the surface profile of the sample through software analysis, enabling fully automated and highly accurate measurements.

FLATSCAN is suitable for non-contact measurements of surface flatness, waviness, and curvature (bowing/warping) on various reflective surfaces, such as silicon wafers, mirrors, X-ray mirrors (multilayer film mirrors/Goebel mirrors), metal surfaces, and polished polymers.

High precision with arbitrary measurement area FLATSCAN provides high measurement accuracy, with a measurement system resolution of 0.1 arcsec and measurement accuracy of 1 arcsec. It offers a repeatability within 100nm for 200mm measurements, fully meeting the requirements of manufacturers and quality inspection departments.

Additionally, the adopted measurement principle has the advantage of being independent of the measurement area. Therefore, for standard measurement surface diameters (200mm), it can be expanded almost arbitrarily without affecting the measurement accuracy.

Larger measurement range, greater working distance The measurement range refers to the maximum arrow height (or minimum curvature radius) that can be measured in a single scan. FLATSCAN has an extremely large measurement range, which cannot be achieved by similar measurement products (such as stripe laser interferometers).

FLATSCAN is not only suitable for flat mirrors but also provides excellent measurement results for reflective surfaces with larger curvatures, such as wafers, X-ray mirrors, and polished plastic products. Furthermore, the optical measurement principle used is independent of the working height. To accommodate different user requirements, we have developed instruments with higher working distances.

Freedom to choose between 2D or 3D measurements Users can choose between single-line scanning (2D) or full 3D measurements based on their equipment type. The software offers various functions for graphical and digital evaluation of measurement results, including 3D images, profile plots, and measurement records.

Film stress analysis For thin films, single or multiple layer coatings, the software primarily calculates the film stress based on Fowkes' theory by measuring the change in substrate curvature radius before and after coating. For example, in the semiconductor industry or other application areas, when the reflective surface undergoes processing (coating or coating removal), operators can utilize FLATSCAN to quickly detect the stress in wafer films.