Product Information/ PRODUCTS /Wafer & Photomask Surface Defect Calibration Standards

Wafer & Photomask Surface Defect Calibration StandardsWafer & Photomask Surface Defect Calibration Standards

specification:

Accuracy and Traceability

Differential Mobility Analyzer (DMA) technology precisely controls the mode (peak) of, and variation in, deposited particle diameter. DMAs are calibrated with Sitraceability using the best availabe particle size reference materials, including PSL spheres from NIST. Calibrations are monitored on a weekly basis.

Precision and Repeatability

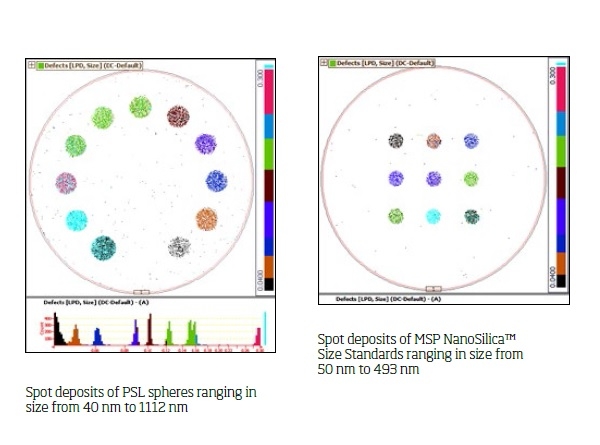

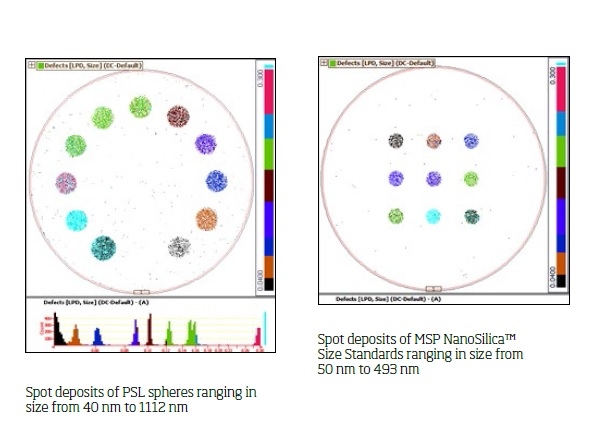

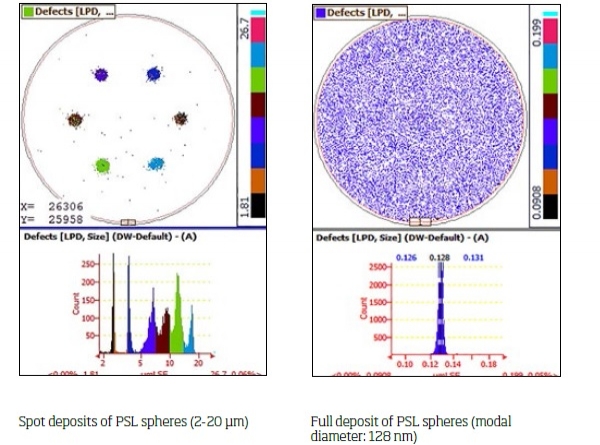

Particle size (10nm to 20µm) and count (400 to >100,000 particles per deposit) are extremely repeatanle from substrate to substrate. Spot diameter (typically 10-30mm) and spot location are consistent from deposit to deposit (adjustable with sub-millimeter precision).

DESCRIPTION

Accuracy and Traceability

Differential Mobility Analyzer (DMA) technology precisely controls the mode (peak) of, and variation in, deposited particle diameter. DMAs are calibrated with Sitraceability using the best availabe particle size reference materials, including PSL spheres from NIST. Calibrations are monitored on a weekly basis.

Precision and Repeatability

Particle size (10nm to 20µm) and count (400 to >100,000 particles per deposit) are extremely repeatanle from substrate to substrate. Spot diameter (typically 10-30mm) and spot location are consistent from deposit to deposit (adjustable with sub-millimeter precision).

Faster Learning Cycles

MSP leads the industry in substrate processing speed. The faster the turnaround, the faster your learning cycle, and the faster your product can be developed.

Certification and Quality Control

Deposited 200mm and 300mm wafers can be inspected with an in-house scanning surface inspection system (SSIS). For photomasks (reticles) and other substrates, MSP deposits particles on a witness wafer and inspects the deposits with the SSIS to qualify the process. Every substrate is handled with extreme care and packaged with our signature triple-warp packaging, preventing contamination during transport.

Customization

MSP will quote and provide a draft recipe for a standard according to your requirements for particle size and composition, deposit count, and deposit pattern type, size, and position on the substrate of your choice. Spot, Arc, Ring, and Full (Blanket) pattern types are available. Over 100 size standards are stocked (10nm to 20µm), and 14 particle materials are available.