Product Information/ PRODUCTS /SITA Cleanliness Monitoring (In-Line) Line CI

SITA Cleanliness Monitoring (In-Line) Line CISITA Cleanliness Monitoring (In-Line) Line CI

specification:

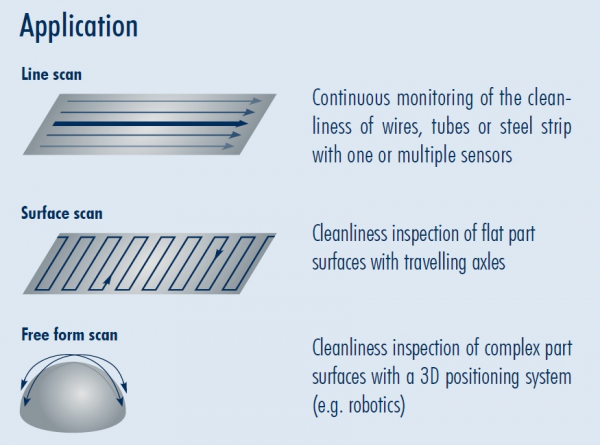

SITA Clean Line CI is an inline fluorescence inspection system that monitors the presence of film-like contaminants (such as oils, lubricants, and release agents) on part surfaces during manufacturing. It can also measure the thickness of coatings (such as rust preventative oils or pre-bonding primers) to ensure consistent quality during subsequent manufacturing processes (bonding, painting, welding, hardening, etc.).

DESCRIPTION

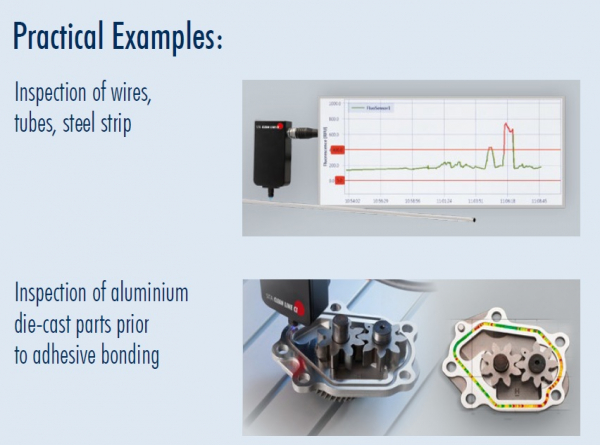

Main ApplicationsCleanliness Inspection: Detecting the surface cleanliness of wire, pipe, and steel strip before coating.

Residue Detection: Checking the surface of aluminum die-cast parts for release agent residue (before gluing).

Functional Surface Inspection: Surface verification after laser cleaning, ultrafine plasma cleaning, and CO₂ snow cleaning.

Primer/Corrosion Inhibitor Inspection: Monitoring coating thickness and uniformity.

Large Metal Part Inspection: Cleanliness inspection before painting and printing.

Contamination Distribution Analysis: Online monitoring of surface contamination distribution during the manufacturing process.

Measurement Principle

Contaminants such as grease and lubricants in industrial processes fluoresce when excited by UV light.

The fluorescence intensity is proportional to the thickness of the contamination layer.

The system uses relative fluorescence units (RFUs) for quantification. The lower the value, the cleaner the surface.

System Features

Non-contact, non-destructive testing

Real-time monitoring and recording for process analysis and optimization

Scalable multi-sensor system supports multi-line or large part inspection

Modular design, hardware/software customization based on process requirements

Can be integrated with robotic arms and automated production lines

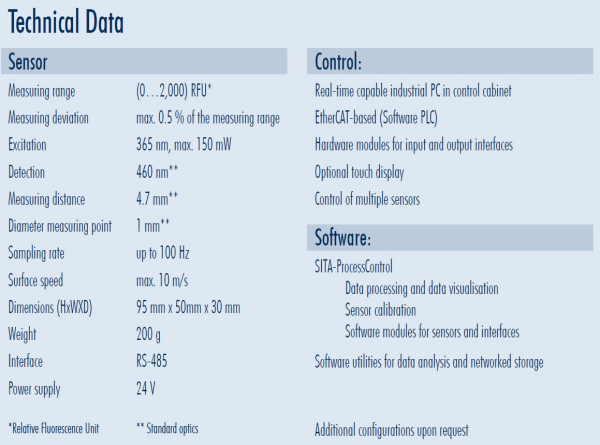

Technical Specifications (Sensor)

Measuring range: 0 to 2000 RFU

Deviation: Maximum 0.5% of measuring range

Light source: UV LED, 365 nm, 150 mW

Detection wavelength: 460 nm

Measurement spot diameter: 1 mm

Measuring distance: 4.7 mm

Sampling frequency: Up to 100 Hz

Surface speed: Up to 10 m/s

Interface: RS-485

Dimensions: 95 × 50 × 30 mm

Weight: 200 g

Power supply: 24 V DC

Control and software

Industrial PC Controller (inside the control cabinet), EtherCAT architecture, supports multiple sensors

SITA ProcessControl software: real-time data processing, visualization, sensor calibration, data storage, and analysis

Supports integration with higher-level process control systems

Optional touchscreen display

Supports networked data access and analysis